Technology

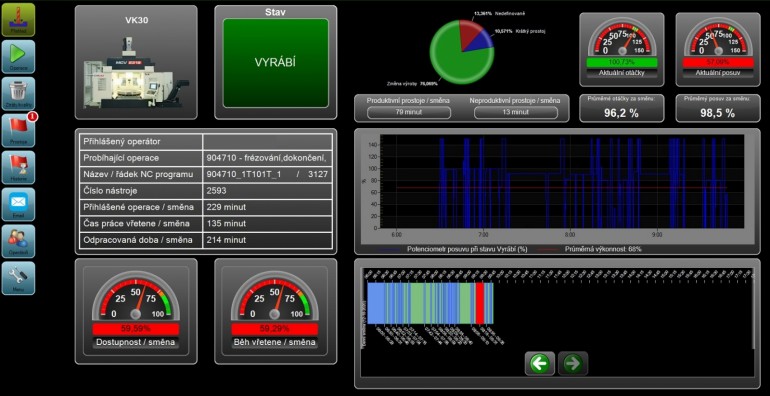

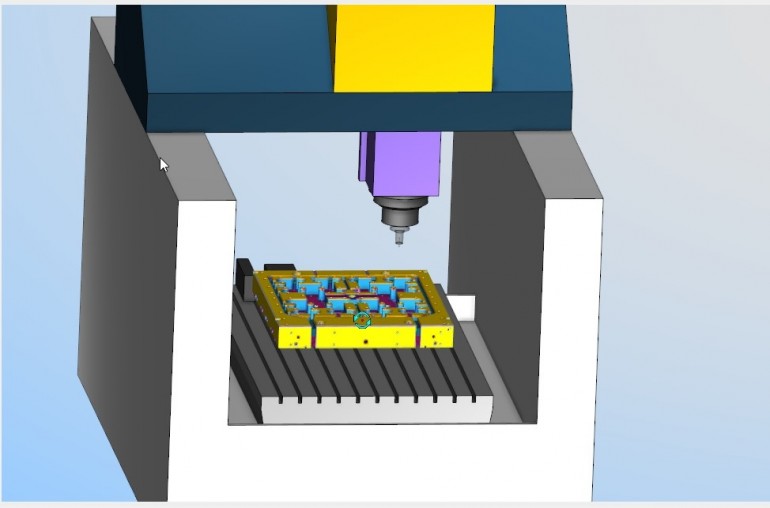

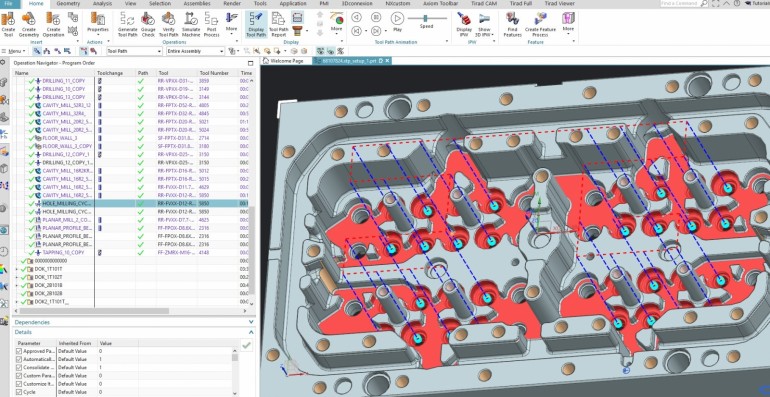

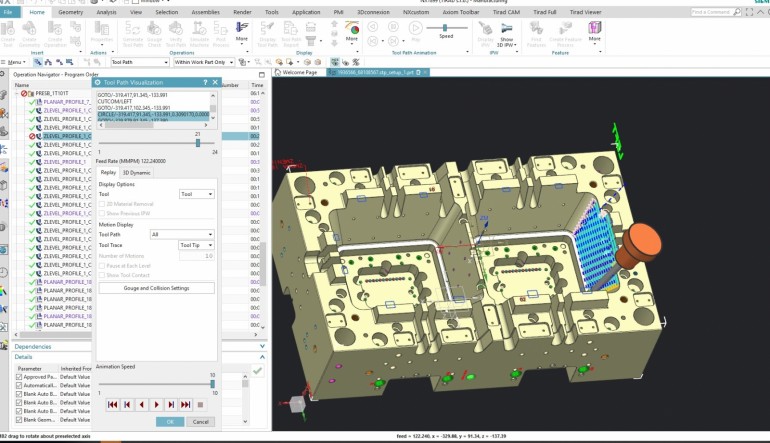

TIRAD knows that the path to the highest quality product is through modern technology and superb training of employee teams. For this reason, we constantly improve our machine, measuring and other technology. We use Industry 4.0 technology for further improving of all processes in TIRAD.

For more specific information, select what interests you: