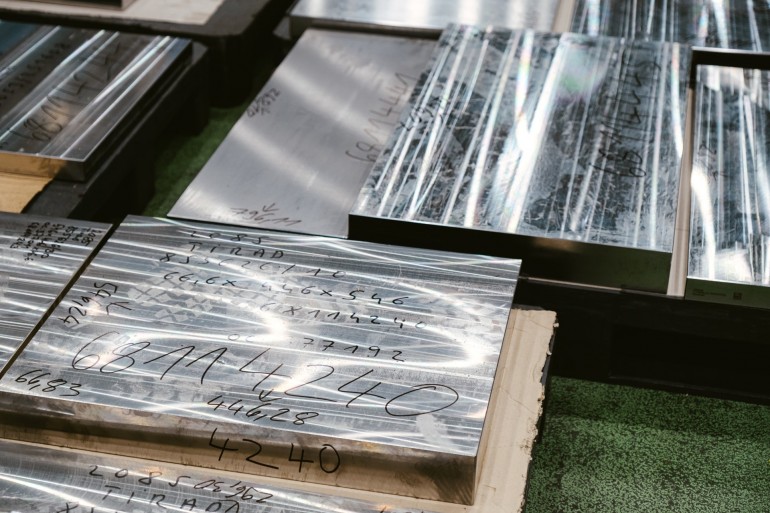

High-Precision Machining

TIRAD knows that the path to an outstanding product is through modern technology and superb training of employee teams. For this reason, we constantly improve our machine, measuring and other technology.

Our Capabilities

Maximum Dimensions

- Frame dimensions to 2300 x 1500 x 1000 mm, 3500 kg

- Position tolerance = 0.008 mm (0.000787”)/1,000 mm

- Diameter/pocket tolerance = 0.01 mm (0.000394”)

Materials

More than 94% of all machined plates are from 1.2085 (X33CrS16)/RAMAX (Uddeholm Sweden X36CrMo17), but of course we can also machine 1.2312 (40CrMnMoS8-6); 1.1730 (C45U; C45W), 1.2343 (X38CrMoV5-1); Roy Alloy, AlMg4,5Mn, etc.

The customer can supply his own material.

We usually machine material from these suppliers: BÖHLER UDDEHOLM, SCHMOLZ AND BICKENBACH, KONTUR WERKZEUGSTAHL, DEW – Deutsche Edelstahlwerke, THYSSENKRUP and others.

Drawing Formats

We use electronic drawings and models in the following formats:

- 2D drawings in PDF (as well as DWG and DXF)

- 3D models in the formats Siemens Unigraphics/NX; PTC Creo/Pro-Engineer; Parasolid; Unigraphics or in the common formats: STEP; STP; X_T (along with IGES; VDA), and, of course, we can work in still other formats

CAM Programming and NC Code Simulation

All programming is done in the CAM system according to the customer’s model. The resulting code is then checked in a verification program, again based on the customer’s model.

For monitoring programmed NC code, we use the VERICUT system to prevent possible contradictions during programming.

You will receive a full report from control measuring of you plate before the shipping. You will be able to evaluate and approve the quality of the plate immediately and this will save your money and time.

You will receive a full report from control measuring of you plate before the shipping. You will be able to evaluate and approve the quality of the plate immediately and this will save your money and time.